Aluminum Heat Treating

Heat treating aerospace aluminum components properly requires unique attention. At our Nadcap accredited facility in Phoenix, we have enhanced our ability to better serve our customers by adding this capability.

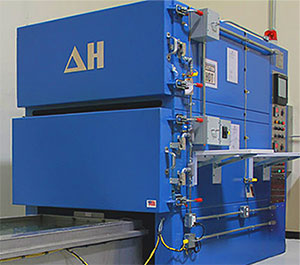

- We use a computer controlled Delta H Technologies model DCAHT® dual chamber oven system.

This system is designed to perform a wide variety of aerospace aluminum heat treating applications; solution heat-treating, annealing, and aging (precipitation hardening).We also use a computer controlled TRU-BLUE II® Rockwell Hardness Tester.

- Nadcap Accreditation – Aluminum Heat Treating per: AMS2770

- Nadcap Accreditation – Pyrometry per: AMS 2750

- HONEYWELL APPROVED SUPPLIER

Moving these processes in house we are able to significantly reduce our delivery times of heat treated aluminum components for our existing customers and offer a new standard for delivery in the industry. Our dual chamber oven system has a chamber size of: 24″ wide by 16″ tall by 48″ deep.

Product Samples

Heat Treat Sample 1

Heat Treat Sample 2

Heat Treat Sample 3

Heat Treat Sample 4

Heat Treat Sample 5

Heat Treat Sample 6

Heat Treat Sample 7

Heat Treat Sample 8

Heat Treat Sample 9